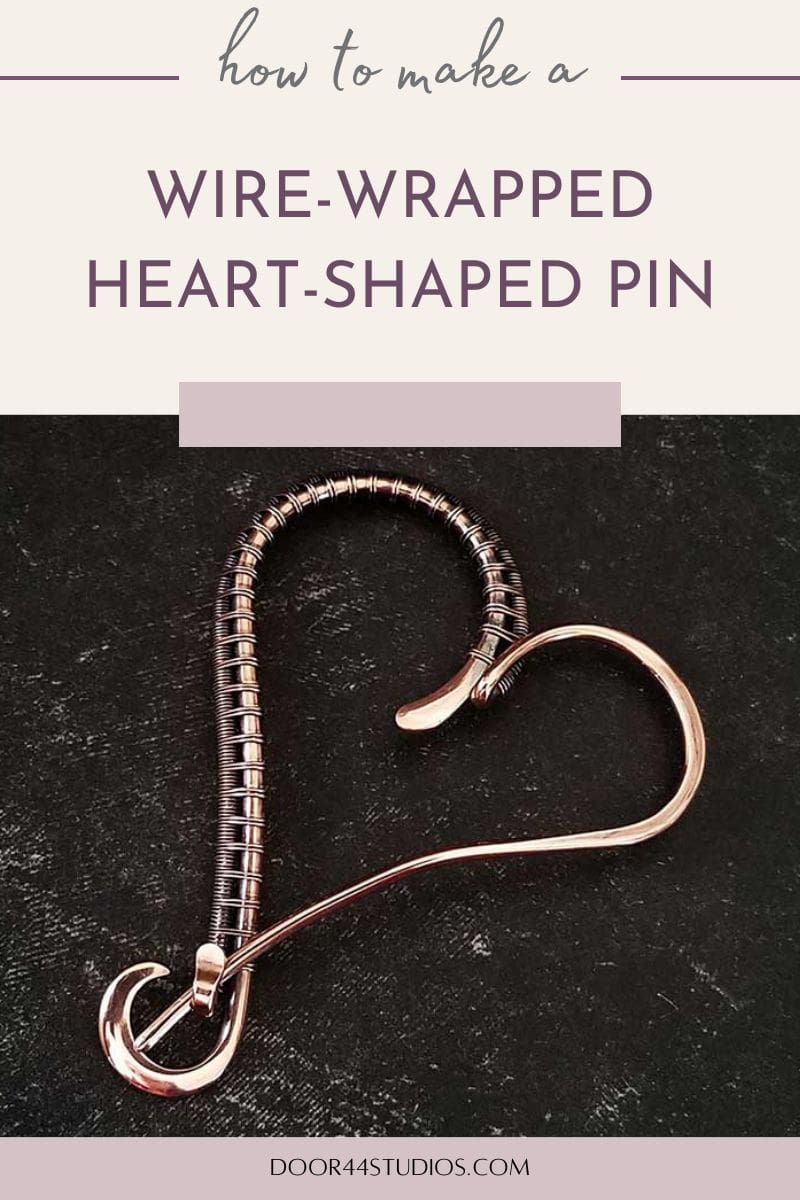

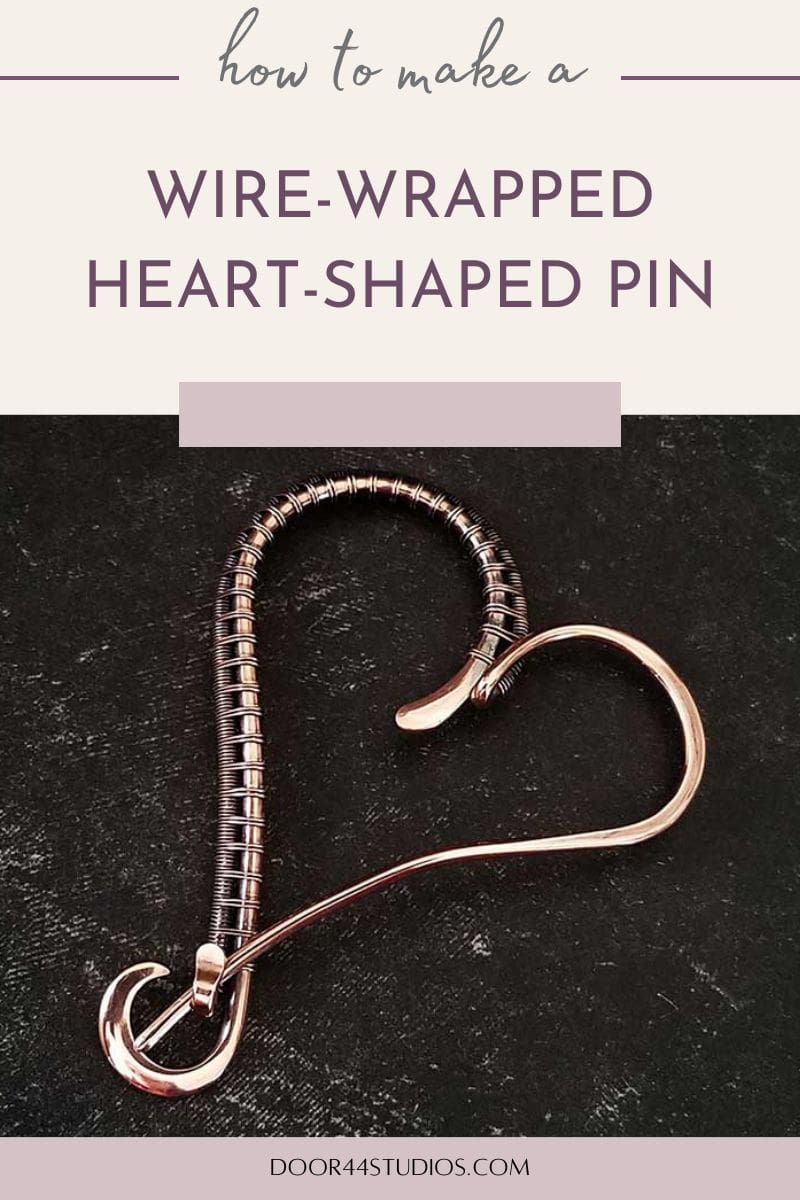

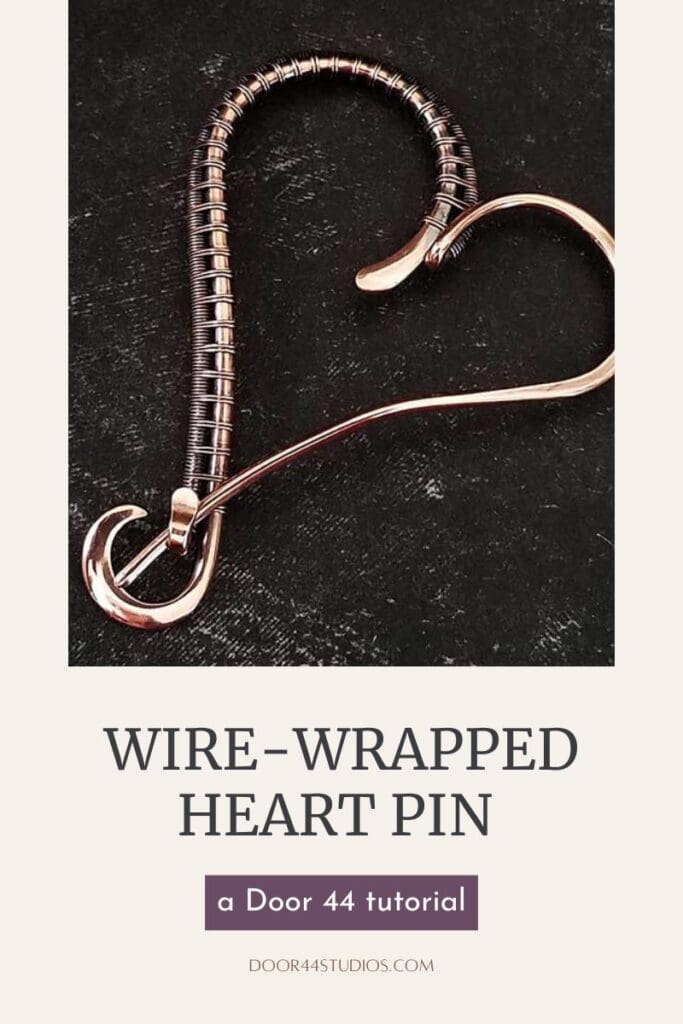

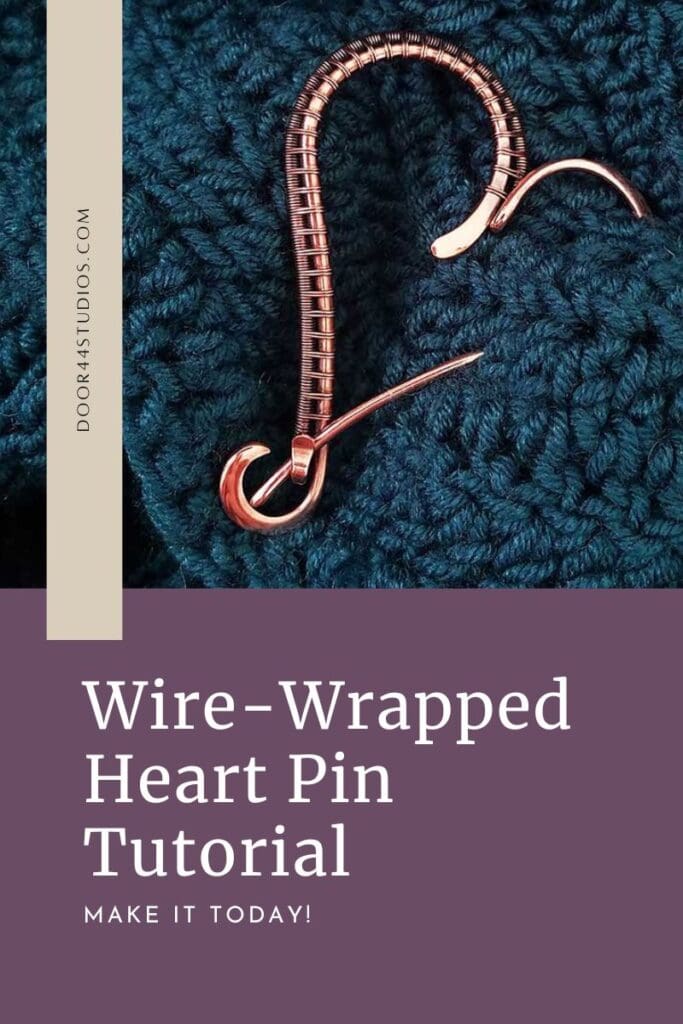

Wire-Wrapped Heart Pin

Do you love to knit or crochet? I’m a bit of a crochet addict myself. And that means that shawl pins are quickly becoming my favorite wirework pieces to create. So, when I made my heart hoop earrings, I knew I had to scale that design up into a gorgeous shawl pin to wear with my favorite scarves. And that’s how this elegant wire-wrapped heart pin came about.

This is what I’d consider an intermediate project because we’ll be doing some basic wire wrapping and working with heavy gauge wires. But with just three pieces of wire to work with, it’s a very accessible project for advanced beginners.

Let’s get started!

Copyright & Disclosure

You’re welcome to make and sell products from this tutorial. When it comes to my written tutorials, however, I reserve exclusive rights to all images and written content. You may not reproduce or redistribute any portion of this tutorial in any way, shape, or form.

This copyright applies to the printable PDF version of the Elegant Wire Wrapped Heart Pin tutorial as well. You may share the free version of this tutorial only by linking directly to this page.

This post may contain affiliate links. If you click on a link and then make a purchase, I may earn a small commission (at no cost to you). As an Amazon Associate I earn from qualifying purchases. To learn more, please see my full disclaimer.

Skill Level: Intermediate

This is a more challenging project that involves wire weaving. It can be achieved by someone who has some basic wirework skills.

Because there’s a full video tutorial for this pin, I don’t go into a lot of detail here on the blog. Experienced wireworkers will have no trouble following along with this abbreviated written tutorial. If at any time you get stuck, be sure to watch the video tutorial here. Or be on the lookout for the much more detailed written tutorial, which will be available soon.

Getting Started

For best results, use solid copper, sterling silver, brass, or bronze jewelry wire. We’ll be working with heavy wire gauges in this project. So, I recommend using dead soft wire for the frame wires. You can also use half-hard wire, if that’s all you have available. But you may find that you need to anneal half-hard wire if you have trouble forming it.

Because we’ll be doing a lot of hammering and shaping in this project, I do not recommend using filled wires. Anytime you hammer the ends of filled wires, you run the risk of exposing the center core wire. That can result in discoloration or an uneven finish, which will become more apparent over time.

Tools & Materials

Finished Size

- WIDTH: about 2 inches (5.08 cm)

- LENGTH: about 2-1/2 inches (6.35 cm)

Instructions

If you prefer video tutorials or if you’re very new to wirework, watch the detailed video version below. Otherwise, keep reading for the abbreviated written tutorial.

The following instructions are written for the 2-1/2-inch brooch that I demonstrated while writing this tutorial. You can modify the size of your brooch by changing the cut lengths of wire and the mandrel diameter. For best results, I do recommend using the heaviest gauge of wire that you’re comfortable forming. I feel that 12ga and 14ga wires work best for this particular design.

Prep Wire for the Main Part of Your Pin

Measure and mark 8 inches (20 cm) of 14ga wire. Then cut your working wire from the spool. Be sure to use heavy duty wire cutters for this step. 14ga wire is a bit too thick for most standard jewelry wire cutters.

TOOL TIP: A standard pair of jewelry wire cutters is typically rated to cut up to 16ga non-ferrous, dead soft jewelry wire. That includes things like copper, sterling silver, brass and bronze wires. Steel wire is ferrous (it contains iron). So, it’s much harder than non-ferrous wires. Never cut any type of steel wire (stainless, blackened steel, memory wire, etc.) with your standard wire cutters. Also, avoid cutting wires that are are thicker than 16ga. Doing so will destroy your wire cutters.

The heavy duty wire cutters that I’ve linked to in this post will cut most types of steel wire as well as thicker non-ferrous wires comfortably.

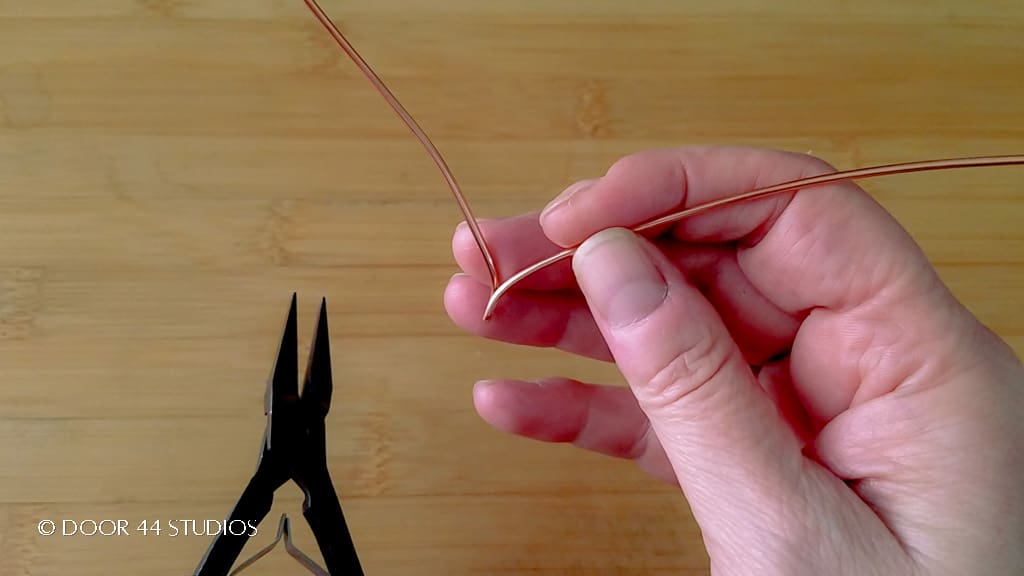

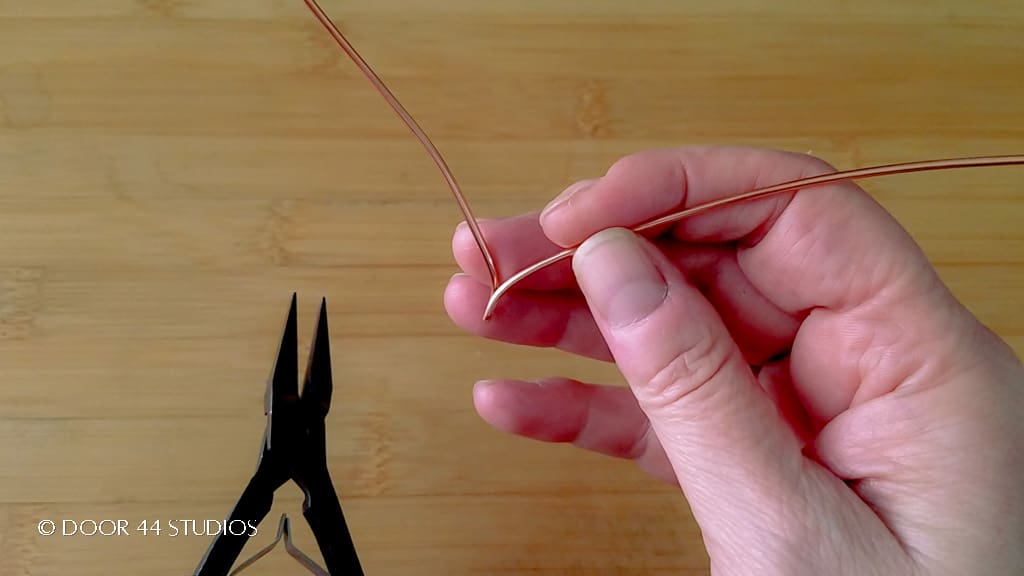

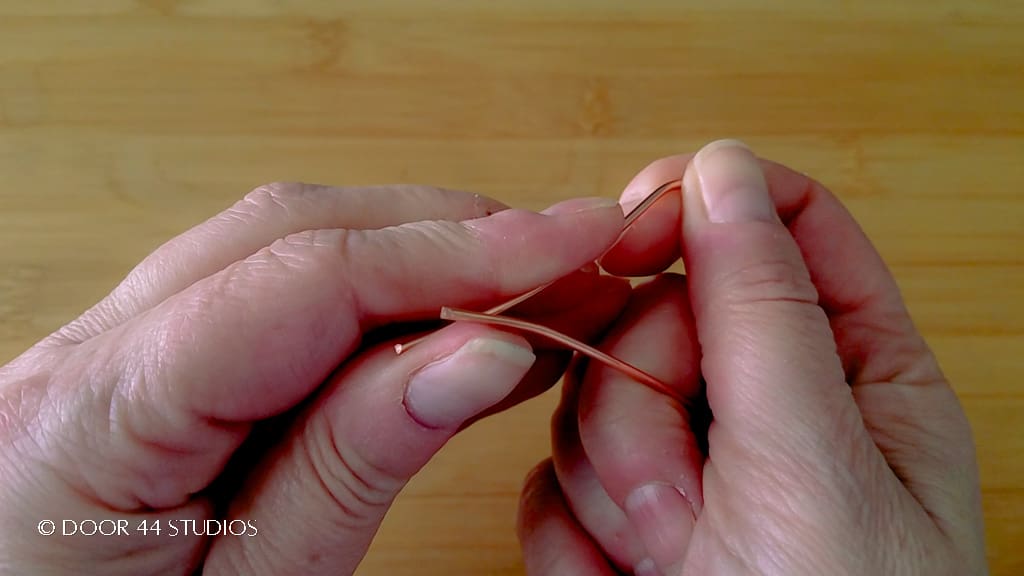

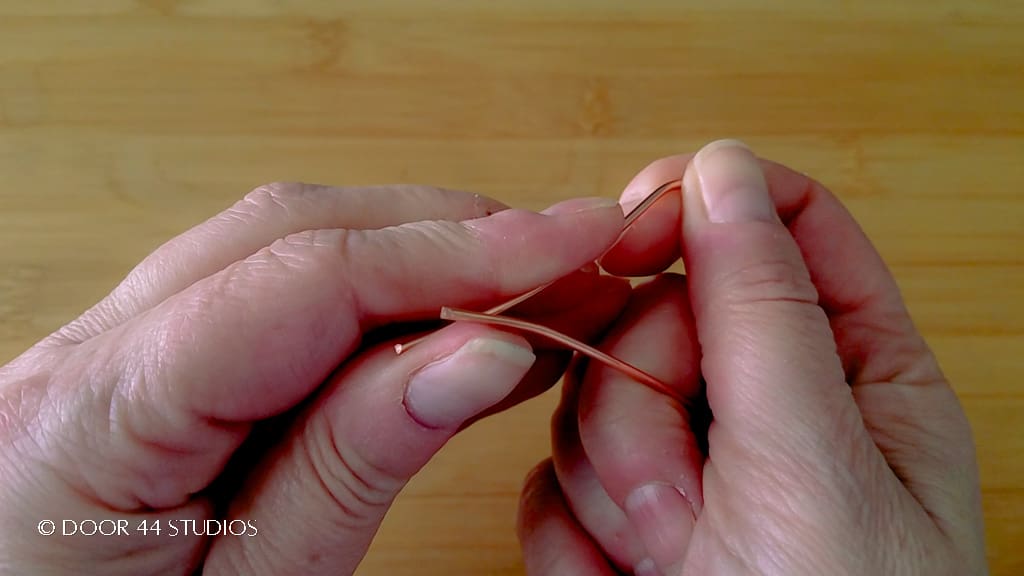

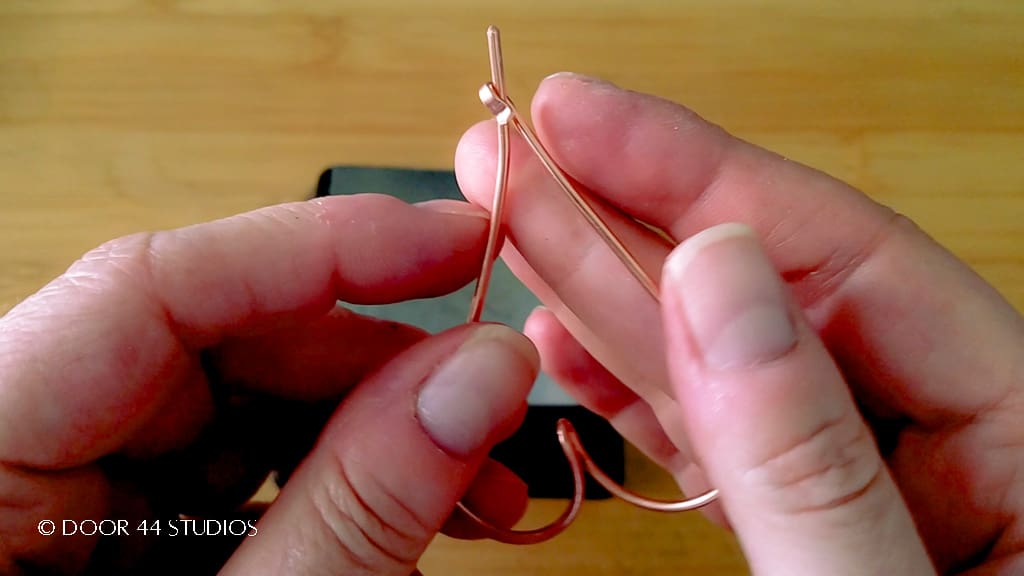

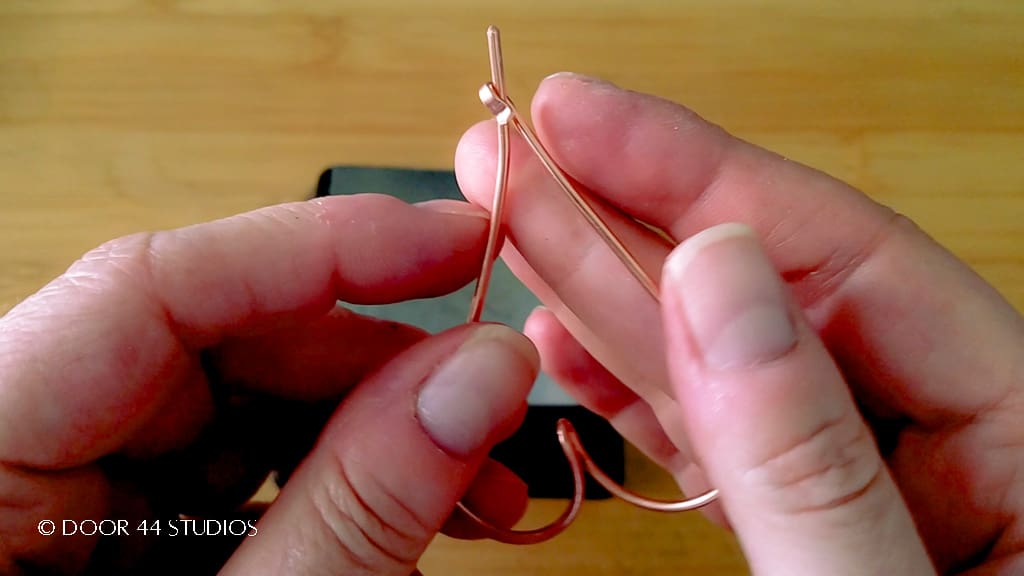

Next, use your flat nose pliers to fold your wire in half, as shown.

Now gently splay the two wire ends away from the center fold, as shown.

Form the Basic Heart Shape

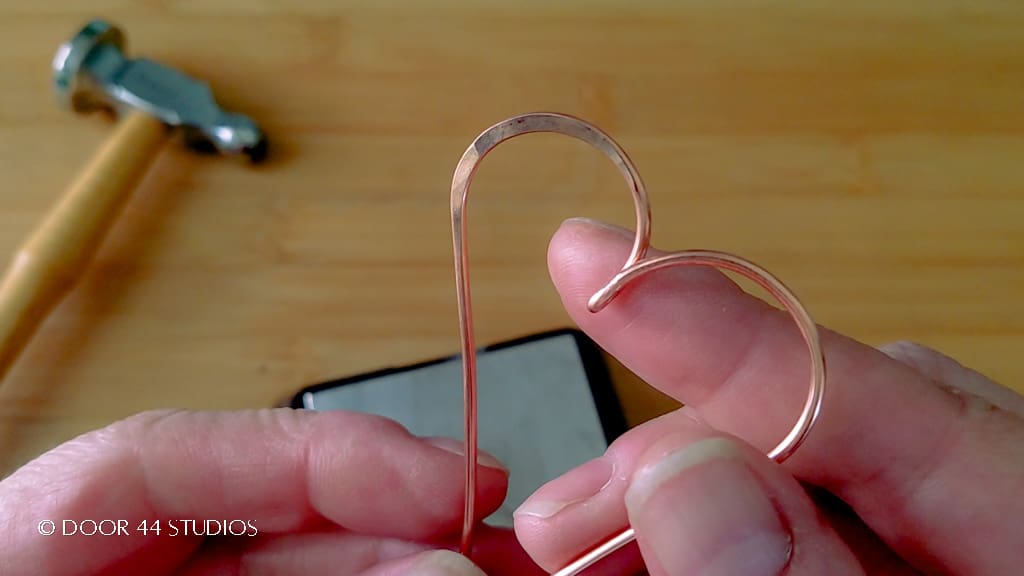

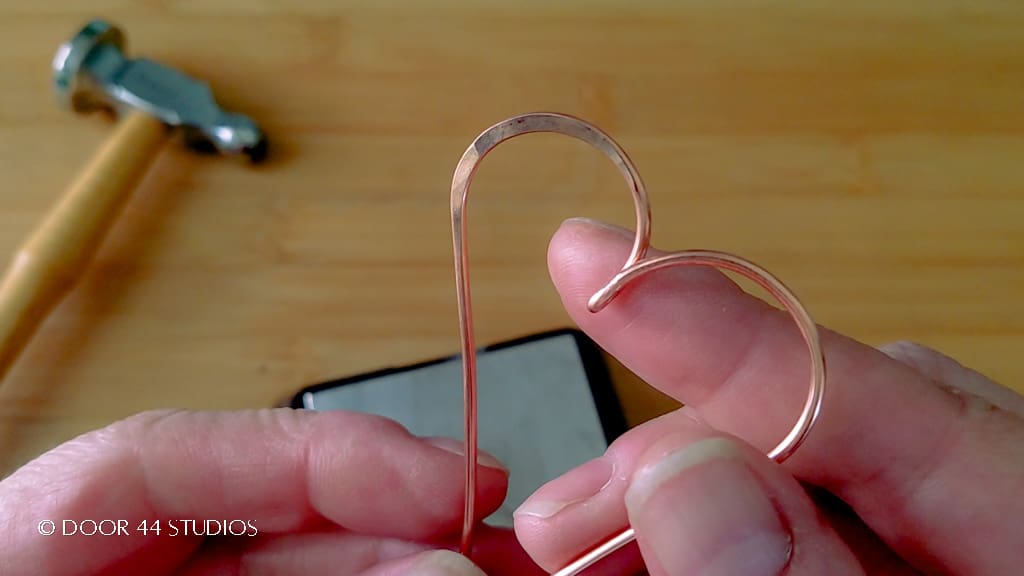

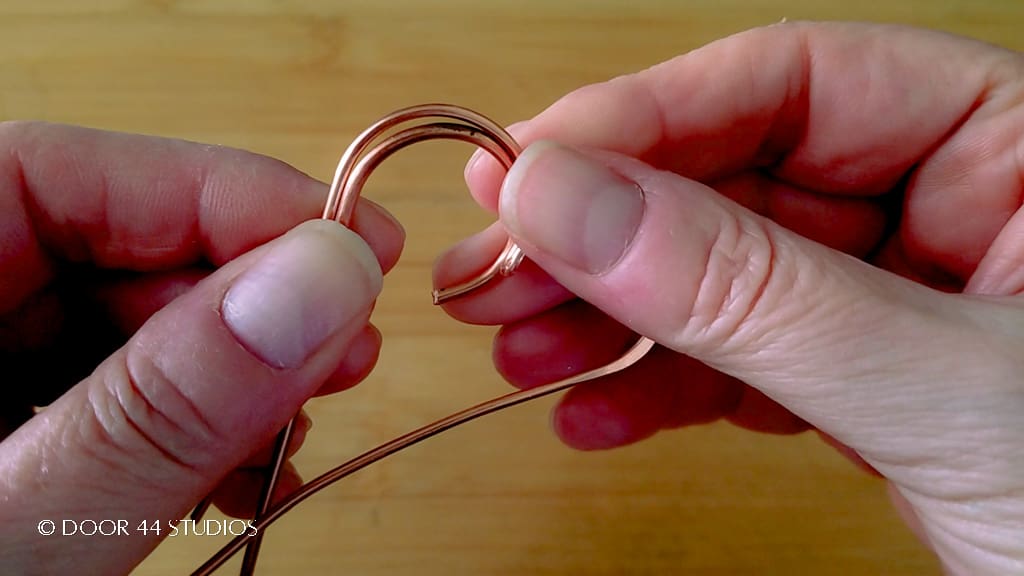

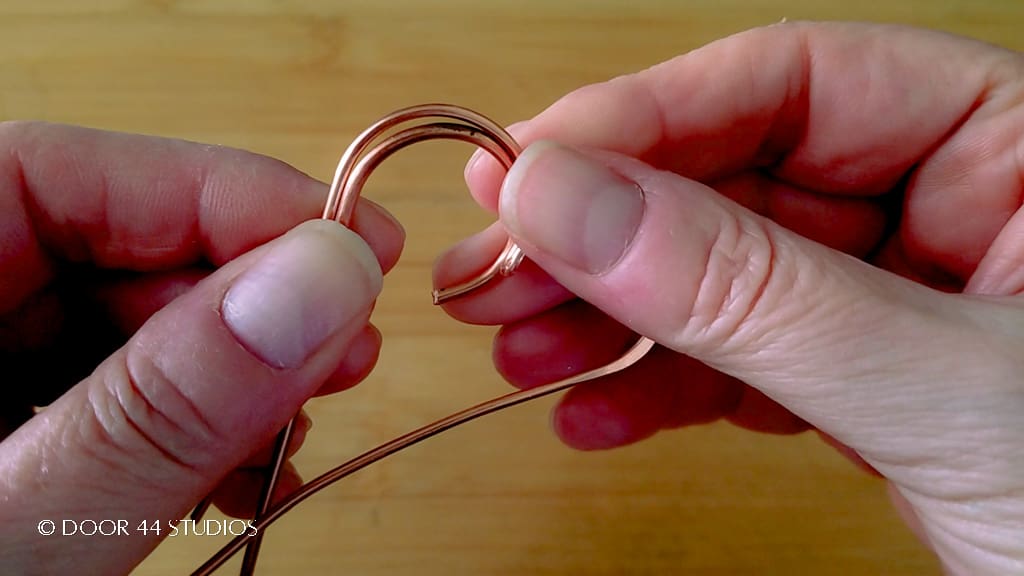

Use your ring mandrel to form the top curves of your heart shape. I chose sizes 7 and 12 on my ring mandrel to create the slightly asymmetrical heart shape shown below. But feel free to use whichever sizes you like to form your own heart.

Next, use your fingers to gently shape the cut ends of your wire into soft, pleasing curves. We’re just adding a bit of dimension here and we want softly flowing lines, as shown below.

This step is optional, but I feel it adds dimension to the finished pin. Use your chasing hammer and bench block to flare out the smaller top curve of your heart. Or the top half of the side that will be your stick pin, if you’re making a symmetrical heart pin.

When finished, your wire frame should look something like the one pictured below.

Form the Second Core Wire

Now that we’ve formed the basic shape of our pin, we’re going to add a second core wire to half of the frame. This wire is what really make this pin pop because it allows us to do some wire wrapping, which adds that beautiful texture that’s unique to wire jewelry.

Measure and cut a piece of 12ga wire to about 5 inches (13 cm). Then curl one end of the wire around your ring mandrel at about two ring sizes smaller than the larger hoop of your 14ga heart frame. I used size 10 on my ring mandrel.

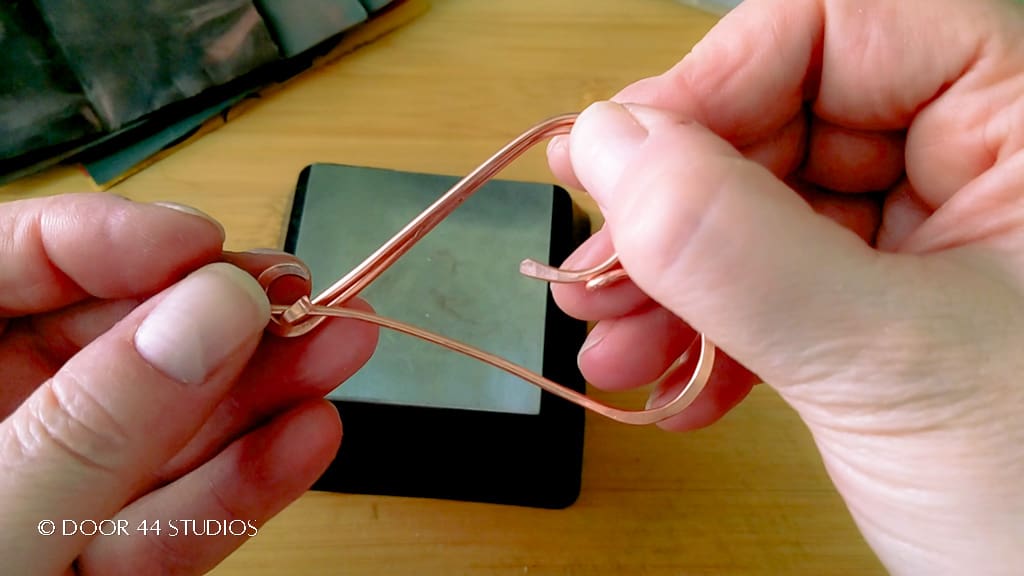

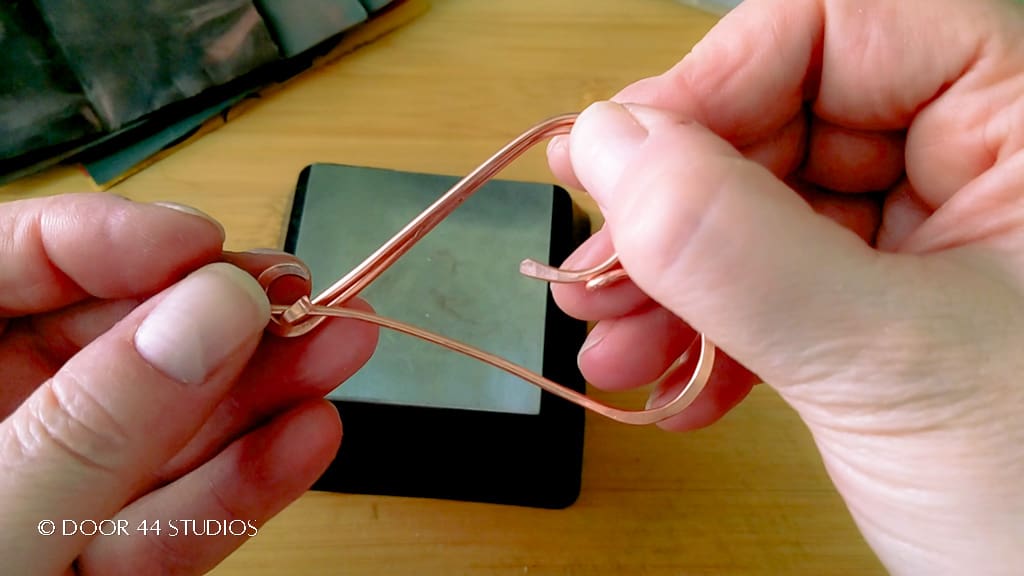

Use a nylon mallet to shape the cut end of the wire neatly around the mandrel. Then test the fit of that curve with your 14ga pin frame. The 12ga wire should nest neatly within the larger curve of the 14ga frame, as shown.

Form the Hook on the 14ga Pin Frame

Before we can finish forming our 12ga accent wire, we need to form the hook on the 14ga pin frame. We’re going to use that hook to determine where to place the final curl on the 12ga accent wire. So, grab your 14ga pin frame and paddle the cut end of the wire on the larger curved side of your pin frame.

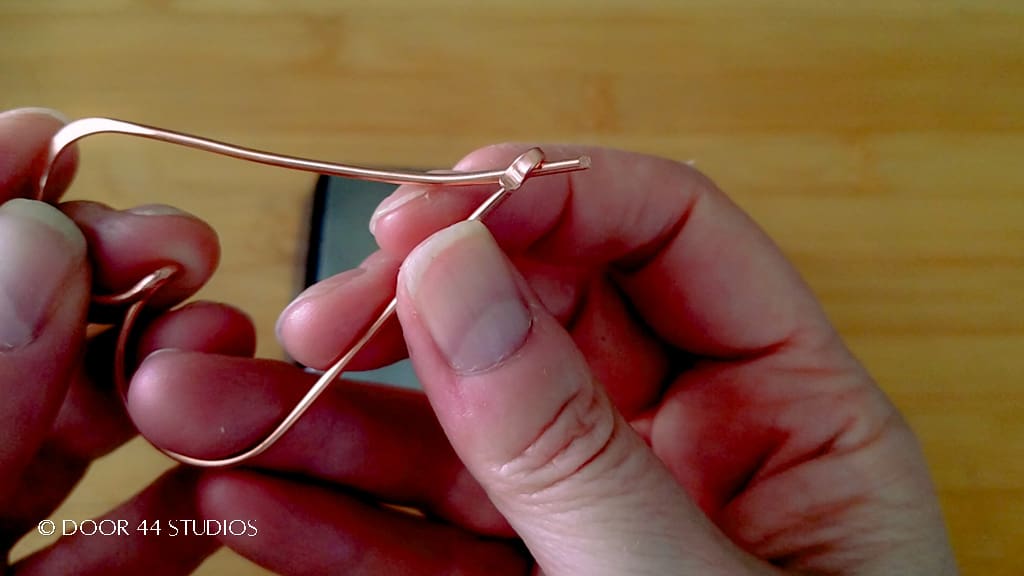

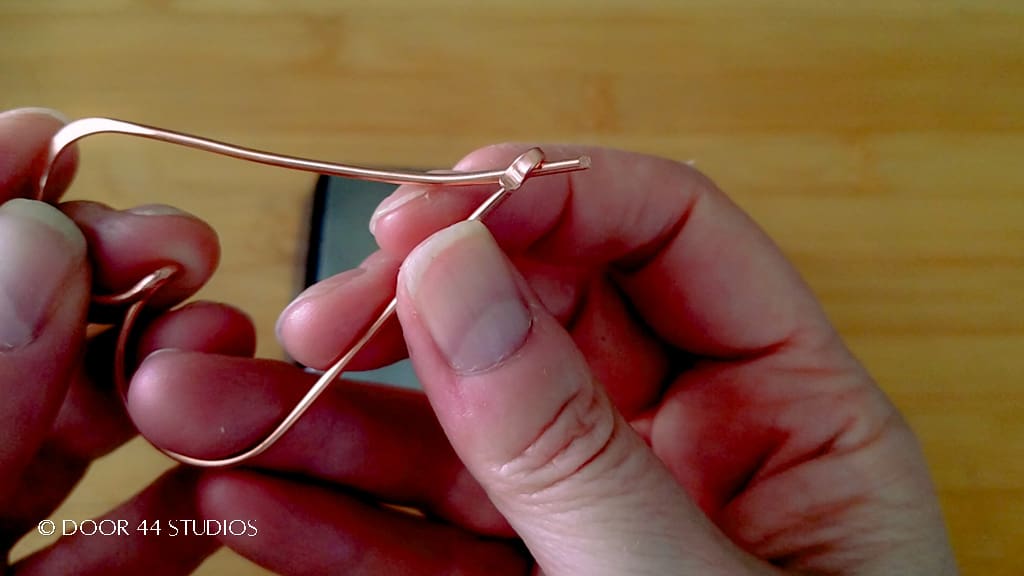

Then use your stepped bail-making pliers to form your hook. I used the smallest step on my bail-making pliers to form the hook pictured below.

Next we’re going to shape the stick portion of the heart frame. Use your needle file to shape the remaining cut end of 14ga wire into a blunt point that looks something like the one shown below. This blunt point allows the pin to glide smoothly through hand knit or crochet fabrics without splitting the yarn fibers.

Now that we’ve fully formed the 14ga pin frame, we can finish shaping the 12ga accent wire. Use the 6mm step (the fourth smallest step) of your bail-making pliers to curl the remaining cut end of your 12ga wire. Place that wire into position on the 14ga frame frequently to see where that curl is formed relative to the hook. Trim any excess wire off the curled end of the 12ga wire once you’re happy with the placement of that curl.

You want the hook to nest neatly within that small curl, as shown below.

Now that your 12ga accent wire is fully formed, it’s time to add those final touches. Use your chasing hammer and bench block to add some drama to the ends of your 12ga wire. As you can see in the image below, I thickened the lines of both ends by using drawing strokes with my chasing hammer. Then I roughly shaped both cut ends of the wire with my needle file.

Sand & Polish the Core Wires

Now that our two core wires are fully formed, it’s time to refine the finish on those wires. I like to soften the lines of the hammered portions of my frame with sandpaper. I also use sandpaper to remove any tool marks that I made while forming the shape.

Inspect both core wires carefully for tool marks and sharp edges. Then use a combination of 800, 1500, and 2000 grit wet-or-dry sandpaper to remove any tools marks and soften the lines of your heart shape. Again, I go into much more detail on this process in the video tutorial. So, refer to it now if you need more help.

Once finished, both wires should have softly curved lines with no sharp edges. The image below shows what my 12ga accent wire looked like after sanding and polishing.

Bind the Two Core Wires Together

The final touch on our heart pin is both decorative and functional. We’re going to bind the two core wires together with a stepped wire wrapping pattern that adds a gorgeous texture to our elegant wire wrapped heart pin. And the addition of the 12ga core wire adds a lot of strength to the pin as well.

TOOL TIP: Managing your weaving wire can be one of the most frustrating skills to master when you’re first starting out on your wire weaving journey. Save yourself some headaches and frustration and invest in some inexpensive plastic Kumihimo bobbins. These little guys are the secret to an enjoyable weaving experience!

Before we begin binding the 12ga wire to our frame, we first need to anchor the weaving wire to that frame. Leaving a tail that’s one or two inches long (2.5 to 5 cm), coil your 28ga wire around the back hoop of your heart frame five or six times.

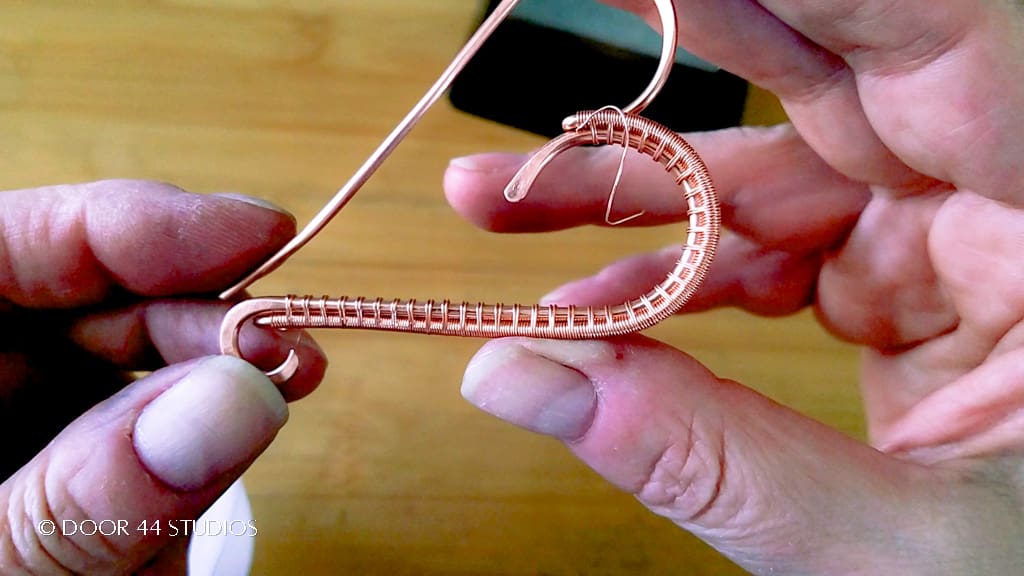

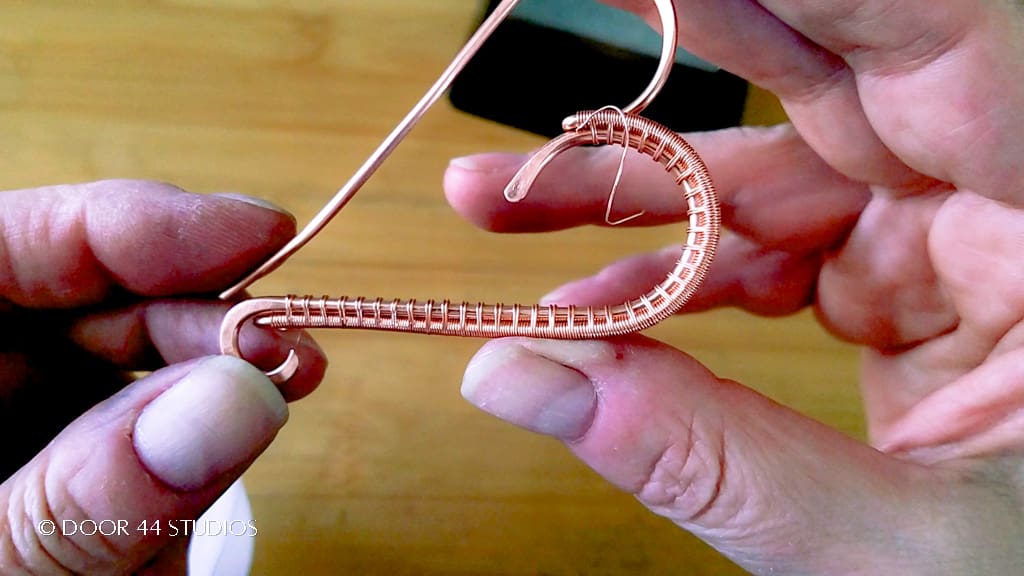

Now we’re ready to start binding the 12ga wire to the frame. Nest your 12ga wire within the 14ga frame, as shown. Then begin binding the two wires together with two snug wraps of the 23ga wire around both core wires. Once you complete two wraps around both wires, make five more wraps around the outer 14ga wire only.

WRAPPING PATTERN: 5 coils around the 14ga (outer) core wire; two binding wraps around both wires. Repeat.

Continue wrapping in pattern until you reach the hook on your 14ga wire. And be sure to compact your weave frequently along the way to keep everything neat and tidy. When finished, your pin should look something like the one shown below.

Once your binding wraps reach the hook, go ahead and complete one final binding wrap around both wires. Then add another five or six coils around the 14ga wire only. Be sure to stop coiling at a point where the two core wires fit together snuggly because we’re going to use that tension between the two core wires to secure the ends of our 28ga binding wire. Then go ahead and break off both tails of your 28ga binding wire.

Sculpt Your Wire-Wrapped Heart Pin Into Its Final Shape

Your pin is structurally complete at this point, but you might notice that it looks a little flat and two dimensional. So, let’s add some depth and dimension with a bit of hand sculpting.

First, test your pin to make sure it slides smoothly and securely into the hook. Then use your fingers to create a soft convex curve on both sides of the heart shape, as shown below.

Now test your stick pin one more time to make sure it still works properly. Make any final adjustments as needed. And that’s it. Your elegant wire-wrapped heat pin is complete!

Finishing Suggestions

I antiqued the pins that I made while writing this tutorial with Liver of Sulfur (LOS). Then I burnished them with super fine steel wool (Grade #0000) in warm water and original Blue Dawn dish soap. The steel wool brings back the bright copper highlights on the high spots.

Next, I rinsed the pins thoroughly to remove any particles of steel wool. And then I put them into a tumbler barrel filled with warm water and a generous squirt of Blue Dawn. I tumbled my pins for about three hours.

If you’re new to wire weaving, be sure to check out my 7-step patina process. And if you’re wondering why I recommend tumble polishing specifically, read this post. Also, be sure to clean your stainless steel shot regularly. Clean shot is necessary to achieve the best finish on your tumble-polished jewelry.

Discover More Behind Door 44

Thanks so much for joining me today. I hope you enjoyed creating this elegant wire-wrapped heart pin.

Want more great wirework tips and tutorials?

I like to share practical wire weaving tips and tricks on my social media channels. And we have some great conversations about wire jewelry in my private Facebook Group. Also, be sure to follow me @door44studios on Instagram, and Facebook to keep up with what’s happening behind Door 44. And if you haven’t already done so, subscribe to my YouTube channel where you’ll find new wire jewelry videos weekly.

Until next time, go make something beautiful!

Pin the Wire-Wrapped Heart Pin for Later